CT-3000

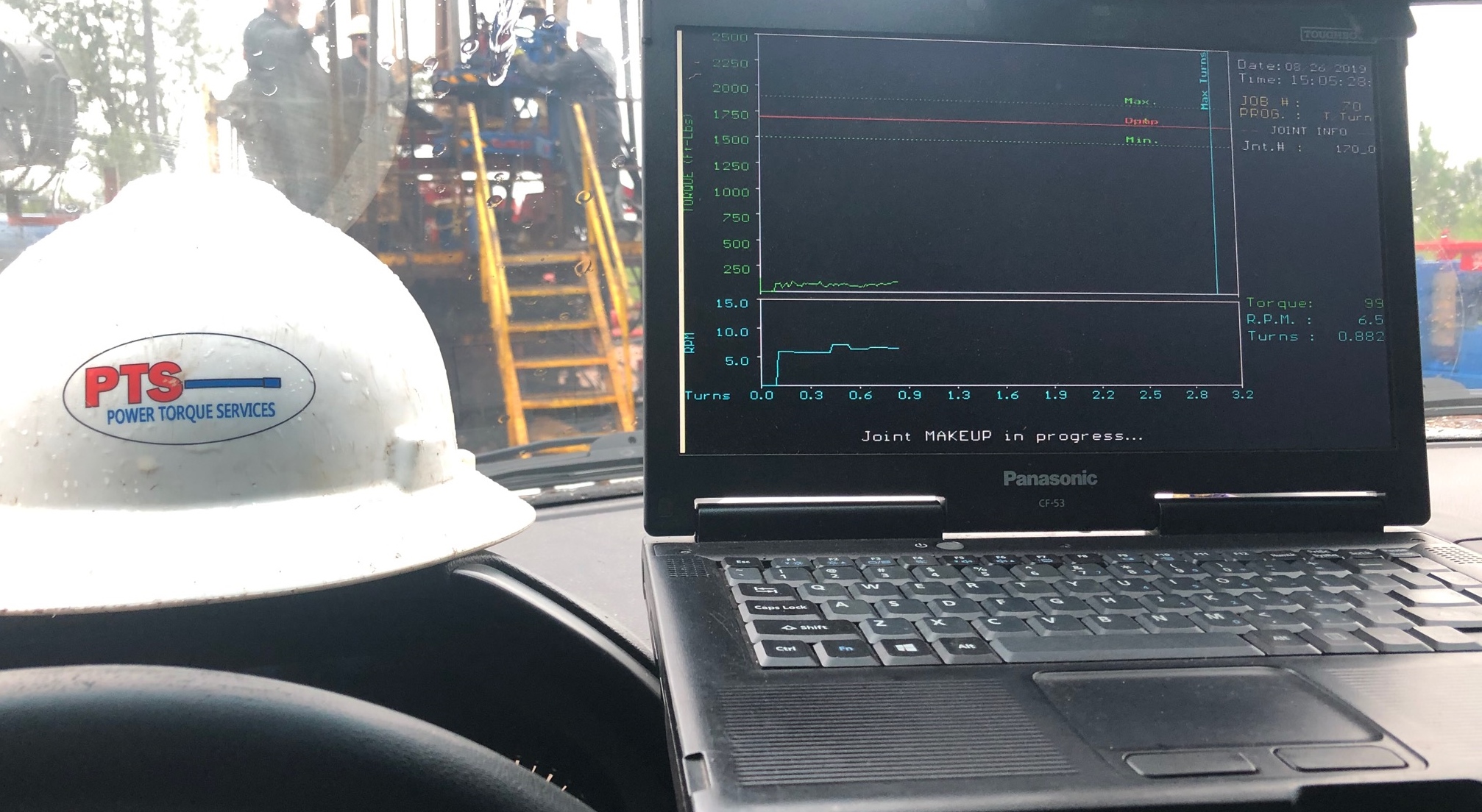

The CT 3000LT Torque Turn System features high resolution graphics with two processors and a choice or four makeup programs, offered in both DOS and Windows based platforms. All PC hardware options are available in a unit that can be built to customer hardware specifications. Several “add-on” modules such as internal pressure testing, and accessories for hazardous area operations are available. Software is “User Friendly” allowing shortened training for field technicians.

CT-4500

The CT 4500 Computerized Torque Turn System has the smallest footprint of any true torque turn system available to the public. As with most of ConTech’s Torque Control Systems, it can be used in the makeup of casing, tubing, drill pipe, downhole motors and accessories, etc. It can be installed on virtually any hydraulic, pneumatic, or manual tong in the field, as well as bucking units in plant applications.

The CT 4500 Computerized Torque Turn System is set up, programmed and operated by the tong or bucking unit operator and mounts directly on the tong and therefore does not require a separate technician. As an option, the CT 4500 Computerized Torque Turn System can also be mounted on the driller’s console, or any location on the rig floor. The unit features real-time graphics and can generate a hard copy report either while running the job, or after job completion. Like all of our products, this unit was designed, programmed and manufactured in house.